Ingredients

- 1. Gelatine powder – 48 grams

- 2. Glycerine – 48 grams

- 3. Water – 240 ml/gram

Tools

- Cooker or stove (optional: temperature controlled)

- Pot, scale, spoon

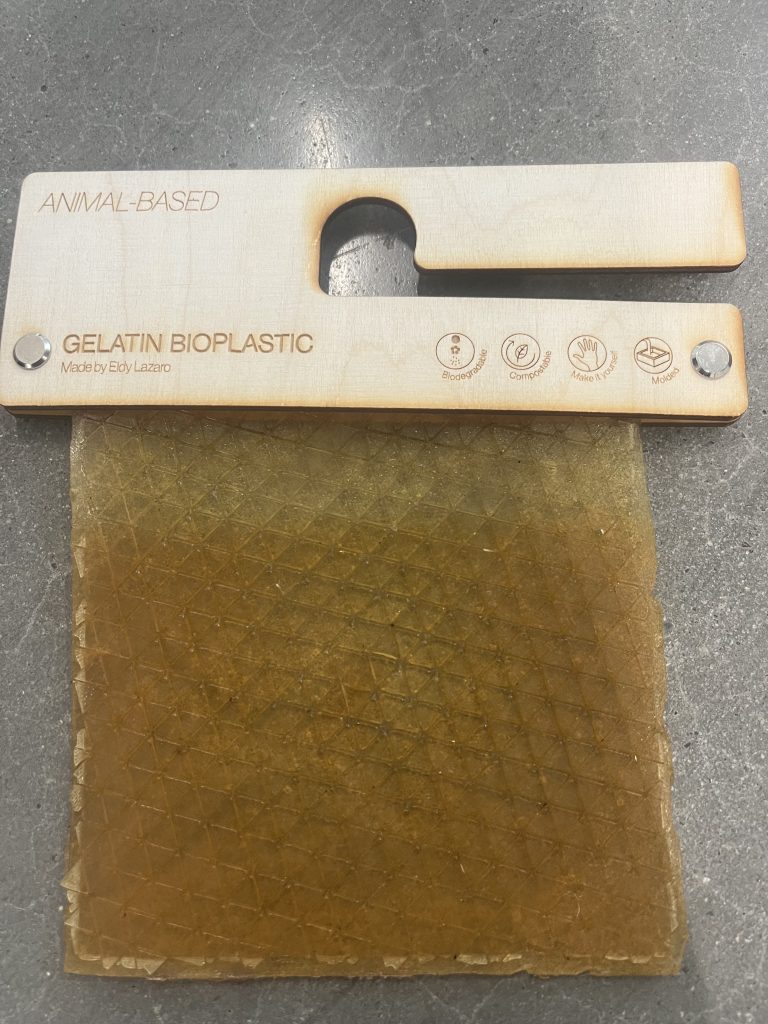

- Molds (use a modular mold or a textured surface).

- Smooth acrylic molds result in shiny bio-silicon)

Method/Procedure

- Preparation

- Weigh your ingredients

- Prepare the mold and find a place where you can leave it for a while, ideally near an open window where there is airflow

- Mixing and dissolving the ingredients

- Bring the water to the boil

- Optional: add natural dye if you wish to use color

- Add the glycerine

- Add the gelatine

- Keep the temperature below 80° C while stirring very very slowly and gently to avoid making bubbles. A simple spoon is preferred to this as opposed to a whisk.

- Cooking the ingredients

- Simmer and slowly stir the mixture between 60-80°C for minutes until it’s like a syrup

- Longer cooking time allows more water to evaporate and as a result, it will shrink less during drying. Make sure it’s still liquid enough to pour.

- Casting

- Cast into the mold slowly to avoid bubbles

- Pour from the middle and hold still, let the liquid distribute itself

- Put the mold away to dry in a cool place with lots of airflow (like near an open window). A warmer place might speed up the drying process but also allow bacteria to grow faster and may

- Drying/Curing/growth process

- Mold Depth: 3×3 mm layers

- Shrinkage thickness: 20-30%

- Shrinkage width/length: 10-20%

- The minimum wait time before releasing from the mold is 3 days. Let it dry for up to ten days to get to the final form. I will be very flexible at first but will slowly harden. Tends to curl up if it is not pressed down during drying(the design of this mold allows for airflow even when pressed). Laying it on a smooth surface helps keep it flat, it “sucks” onto the surface.

- Post Processing

- Trim, cut, or process the slab before it is completely dry and hardened for nice clean cuts. Store in a dry and ventilated room.